ENGINEERING

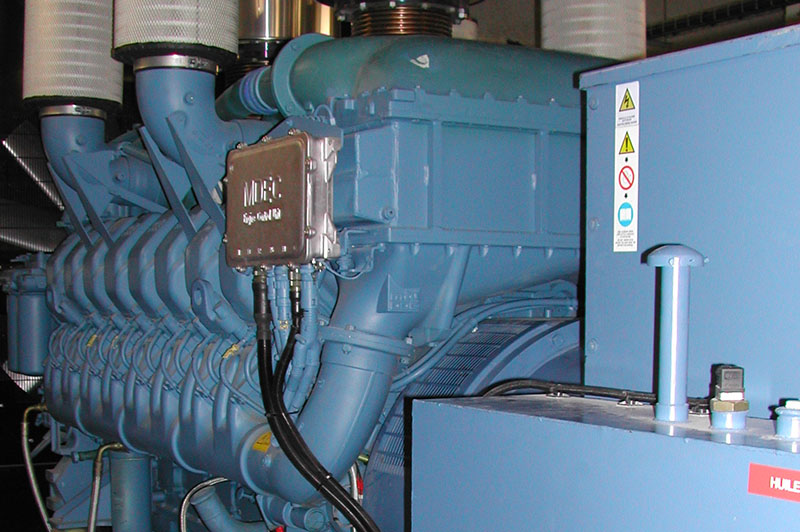

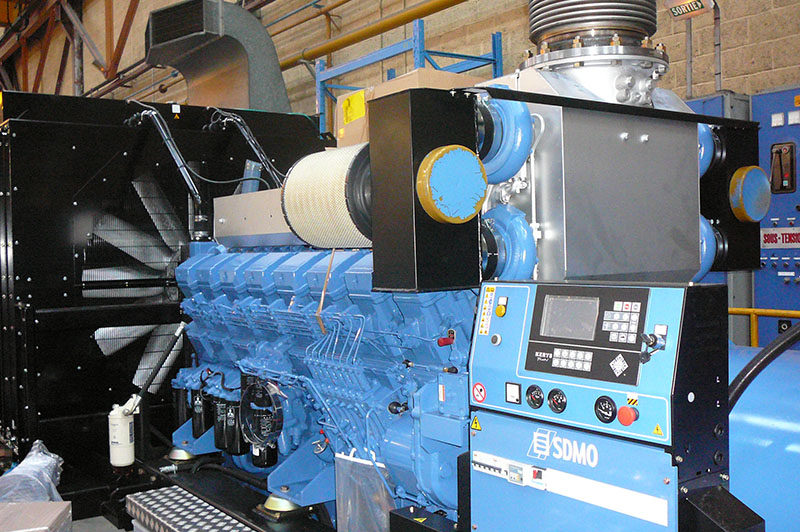

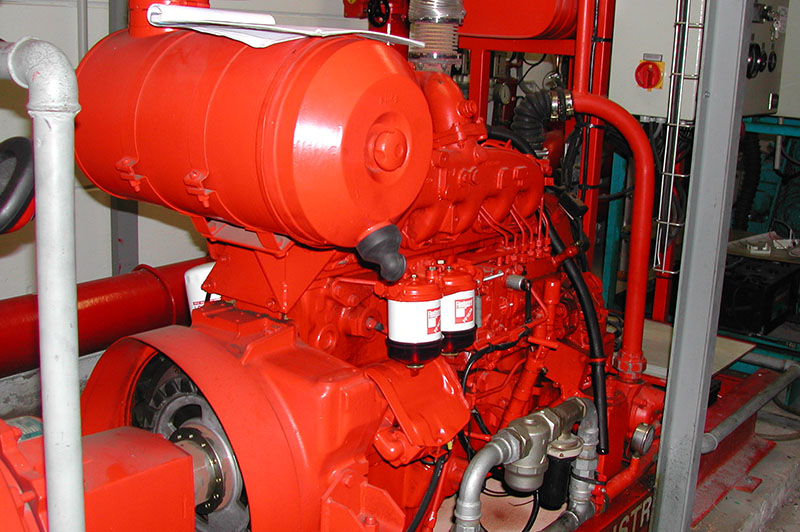

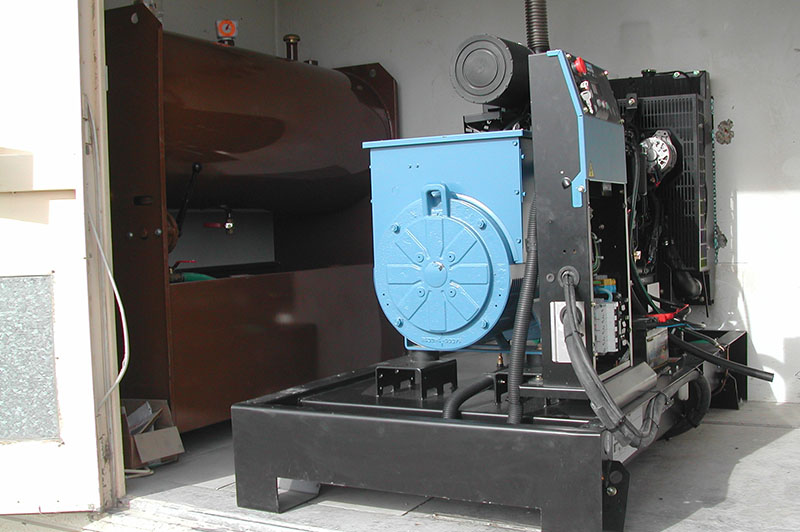

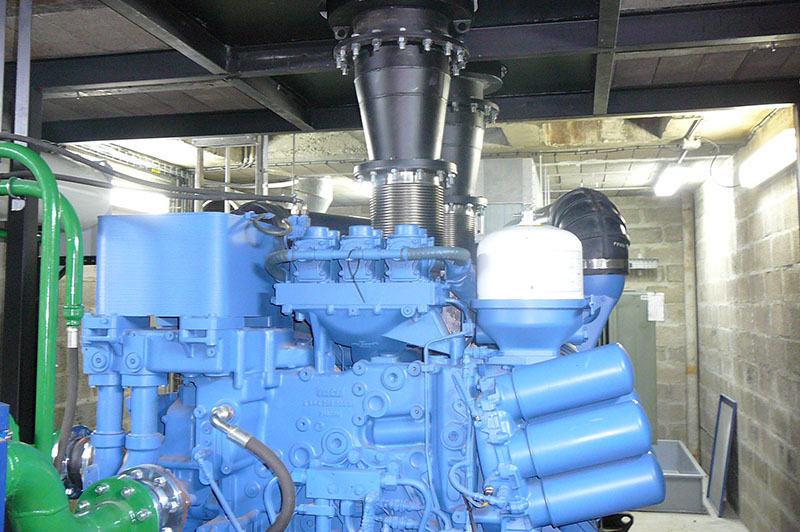

Power generators

Sale and installation of industrial generators

- Electrical, acoustic and ventilation pre-study: dimensioning of materials to meet specifications (electrical cables, circuit breakers, sound traps, exhaust silencers, air inlet and outlet grilles, fans…)

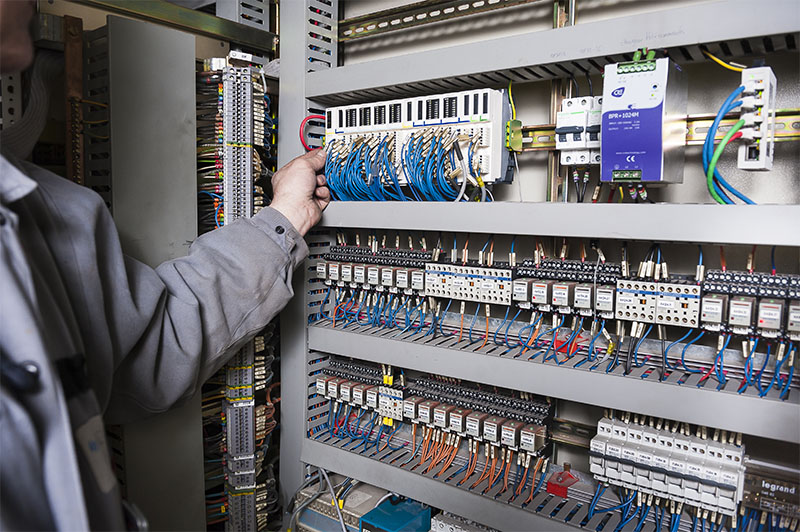

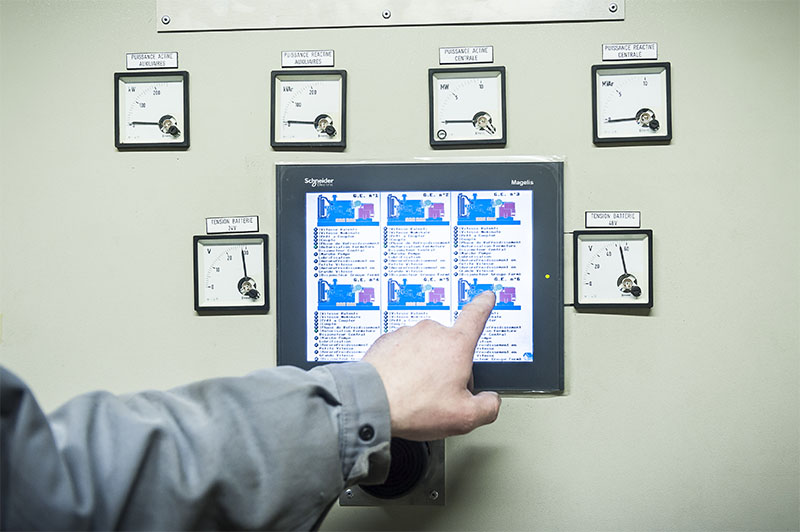

- Automation solutions: development of “open” automation systems, adaptable to specific customer requirements

- Specific functionality: redundant automation, degraded operation

- Determination of the material and implementation solution best suited to the user’s needs.

- Comparative study of different technical options.

- Power study

- Study of the implementation and consideration of environmental constraints

- Project Preparation:

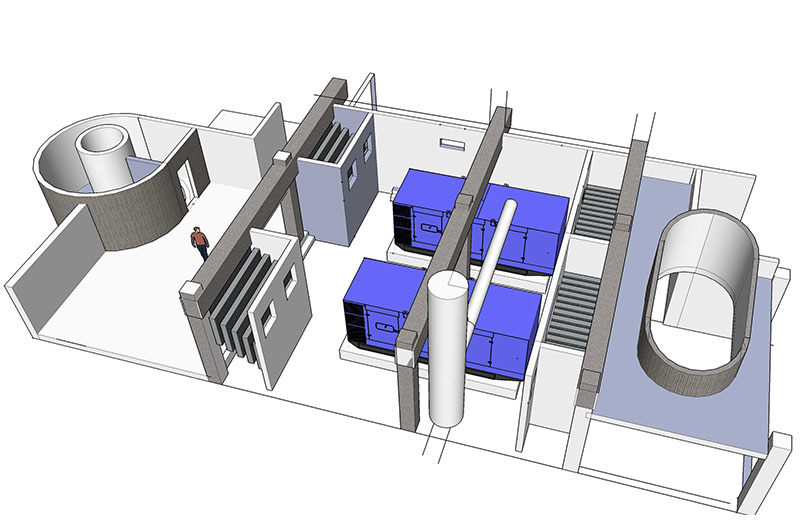

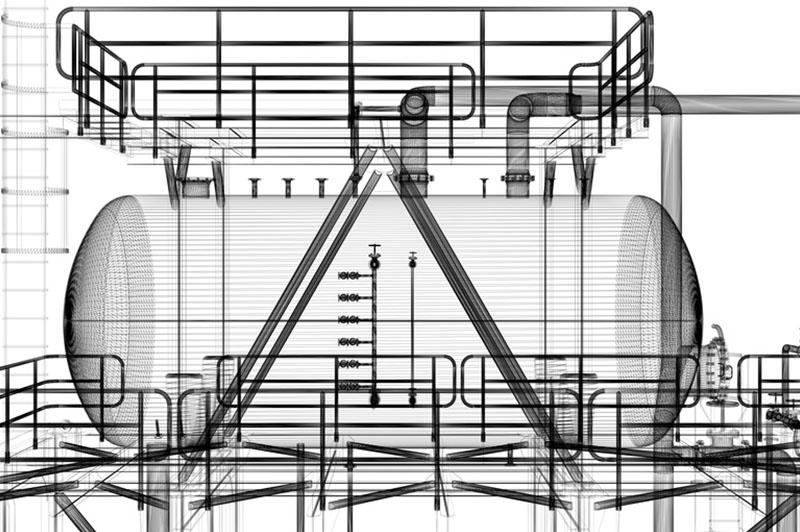

- 2D and 3D plans of the layout

- Acoustic study

- Sizing of sound attenuation equipment: soundproofing rooms, soundproofing panels, etc.

- Autonomy

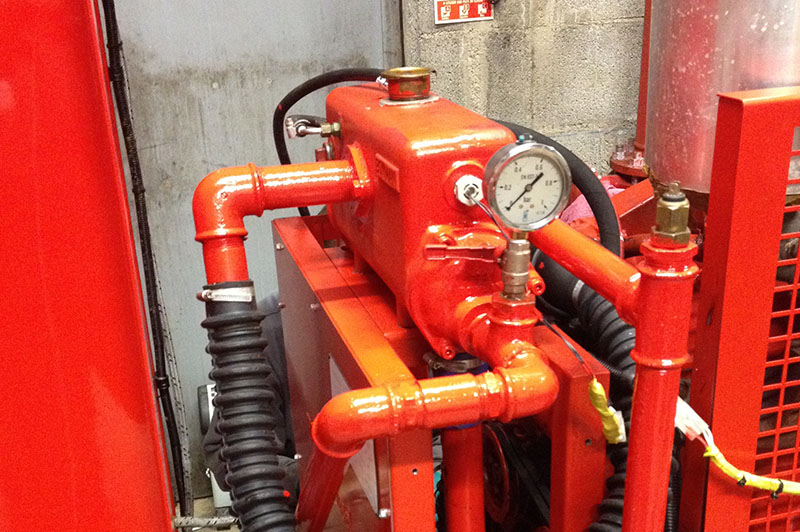

- Fuel tanks, implementation and connections

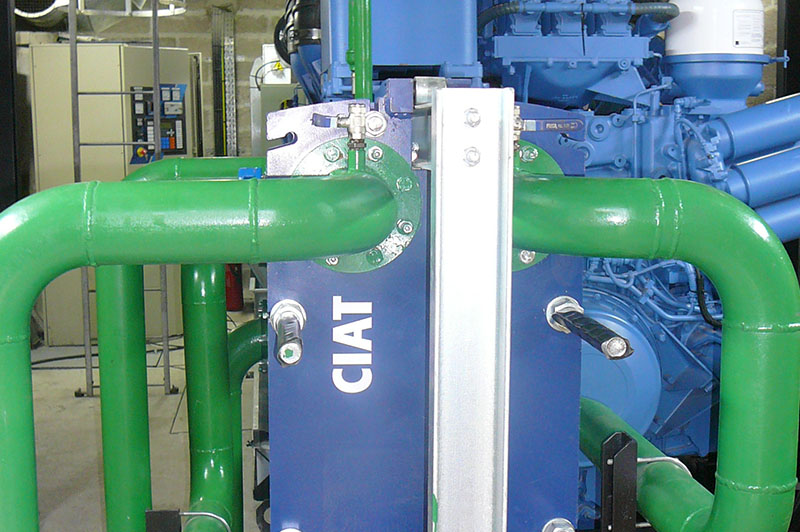

- Refrigeration study

- Ventilation study

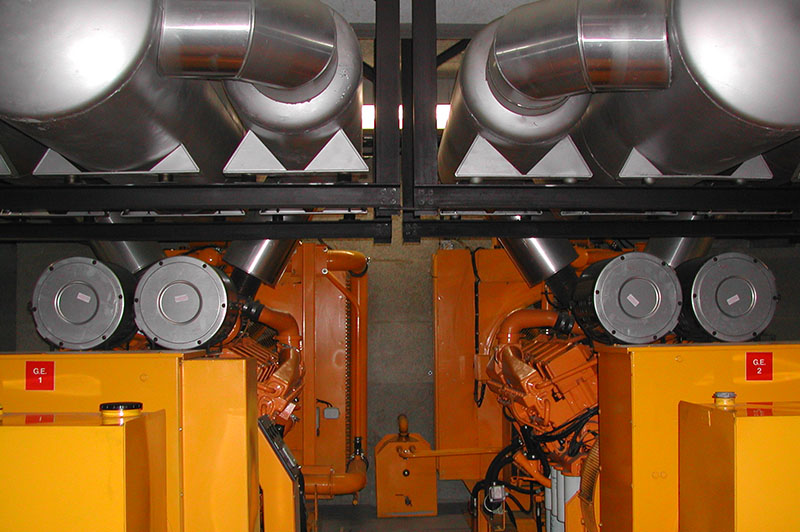

- Sizing of air inlets and outlets, ventilation grilles

- Sizing of radiators, air coolers, fans…

- Calculation of pressure losses and sizing of installation accessories

- Exhaust system

- Consideration of environmental constraints and determination of the silencers and circuit adapted to the constraints.

- Calculation of pressure losses and dimensioning of conduits

- Electrical study

- Calculation of the possible automatic correction devices of cos Phi (capacitive benches, inductive benches) and the associated automations

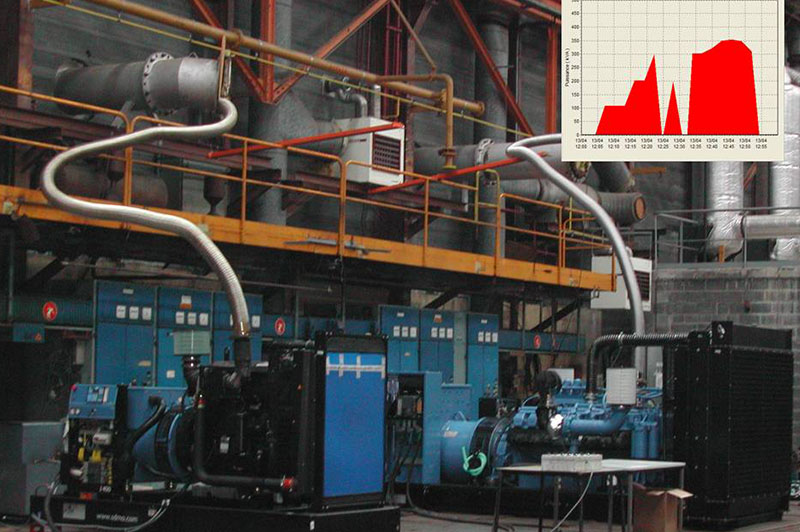

- Predetermination of the load and possible automatic load devices (resistive load steps in automatic)

- Sizing of protections and cables

- Security

- Determination of safety accessories

- Acoustic study

- Definition of test procedures on the platform

- Definition of commissioning procedures

- Automation solutions: development of “open” automation systems, adaptable to the specific requirements of the user for all types of situations:

- Production, stand by, deletion, clipping

- High and low voltage

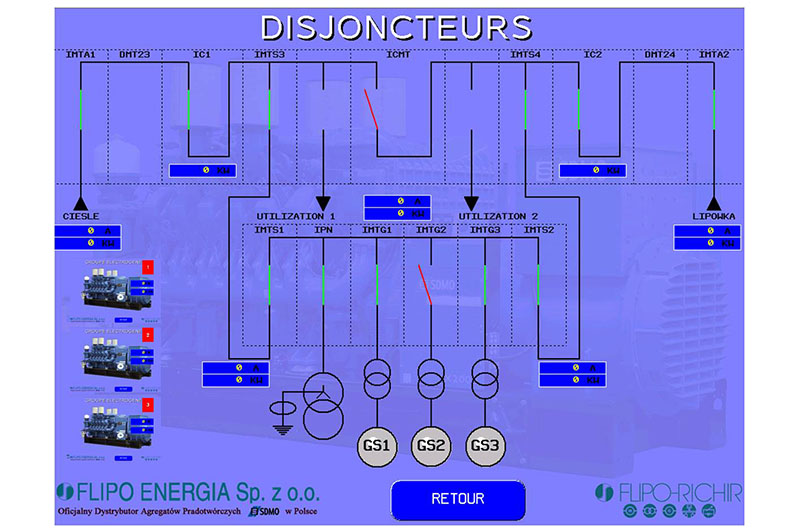

- Normal backup inverter, coupling between groups, fugitive or permanent coupling to the network or to several networks

- Hot or cold redundancy

- Degraded operation

- Remote maintenance

- 2D and 3D plans of the layout

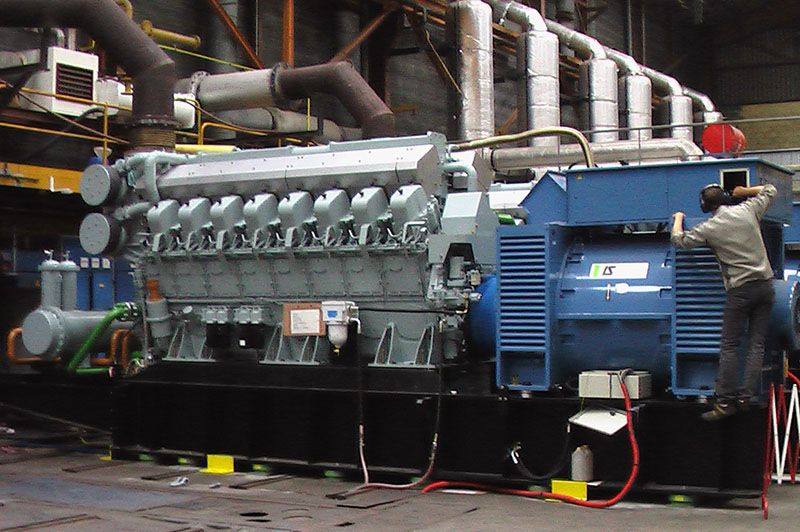

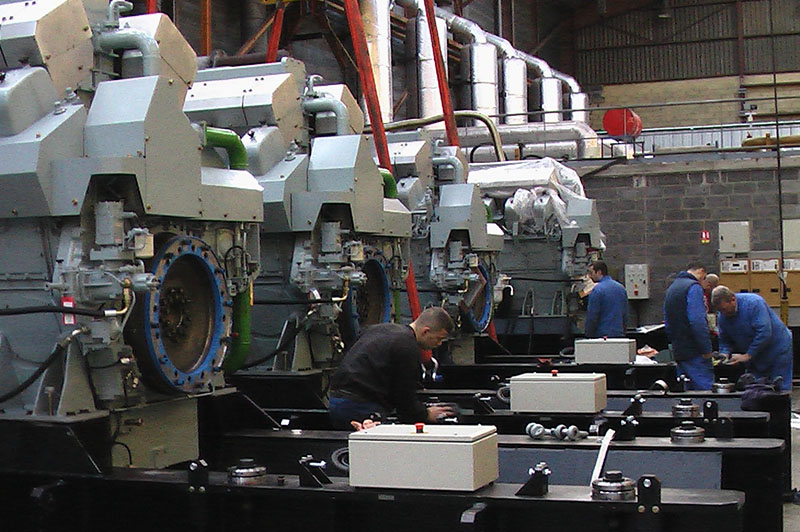

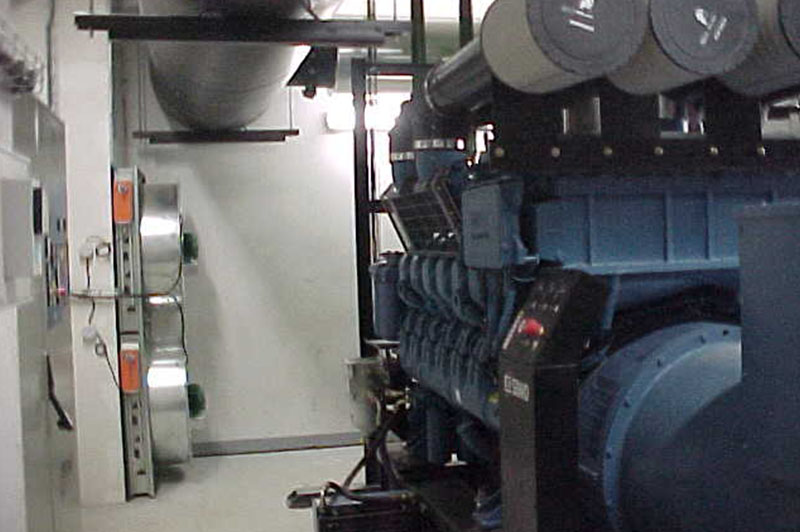

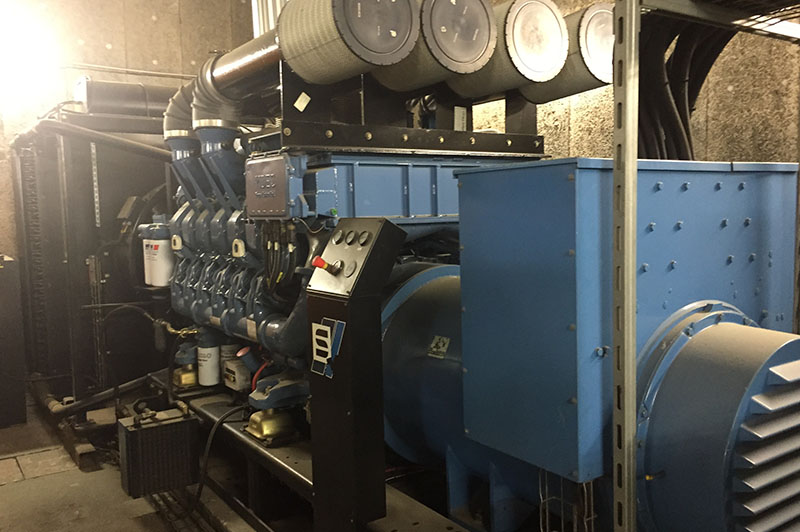

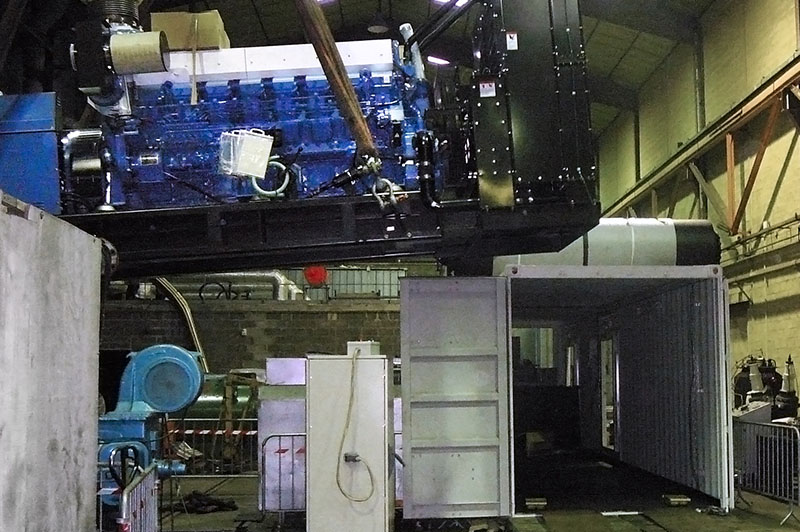

- Handling: complete dismantling of an old industrial generator installation, installation of generators and all the elements necessary for their operation, regardless of their weight or place of installation (on an external slab, in the basement, on the roof…)

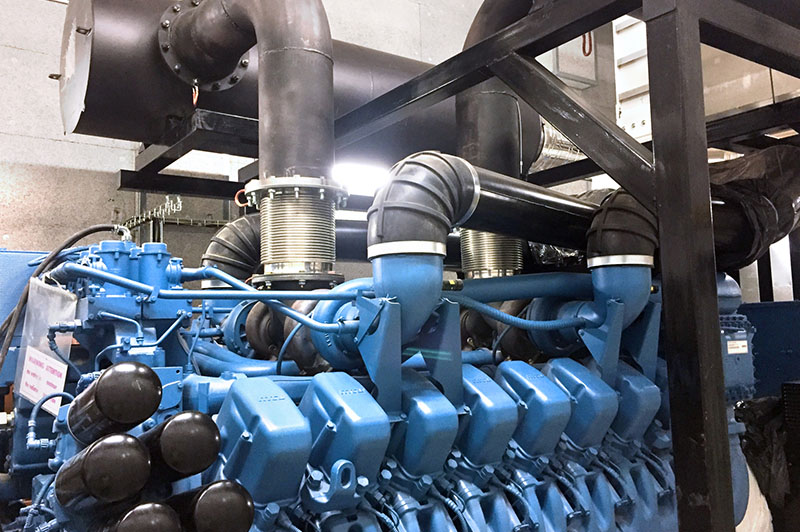

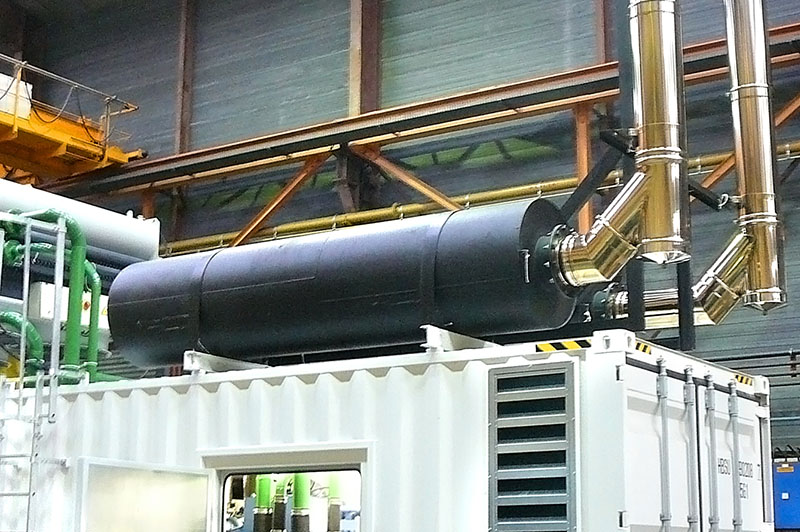

- Exhaust: installation of exhaust silencers and smoke evacuation ducts, connection and insulation of the various elements

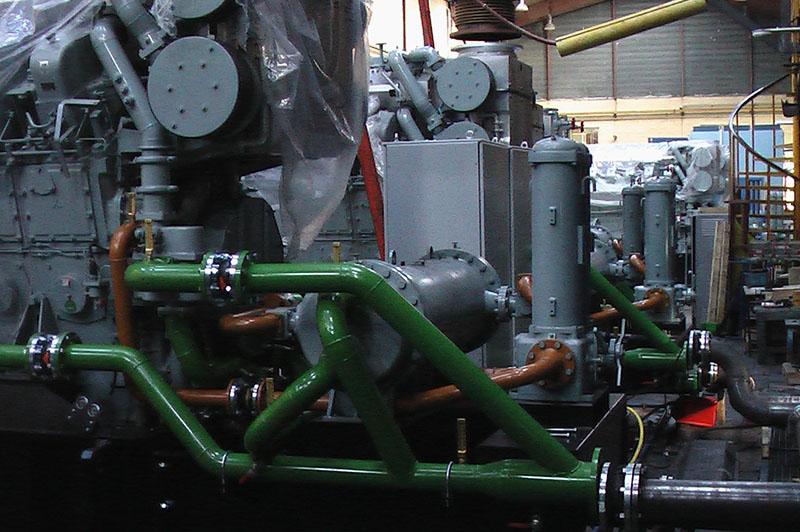

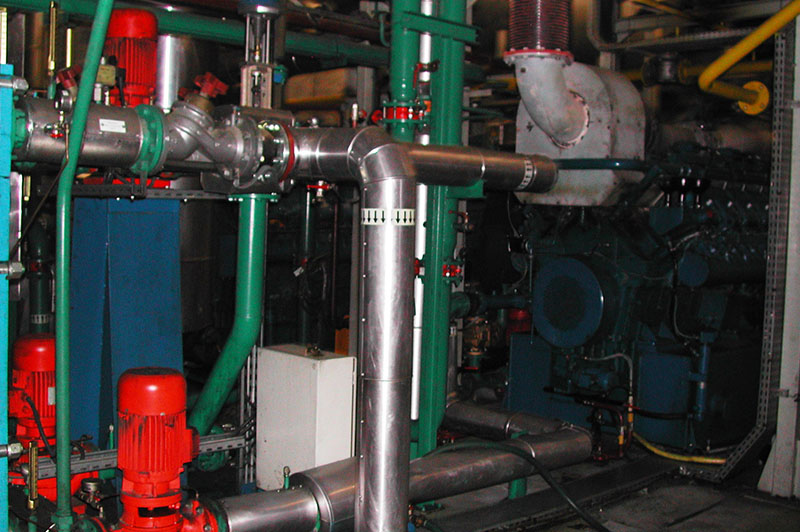

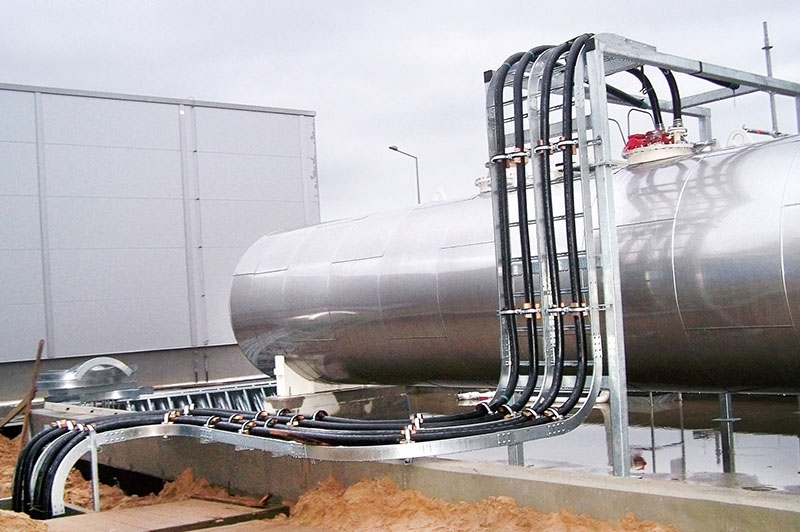

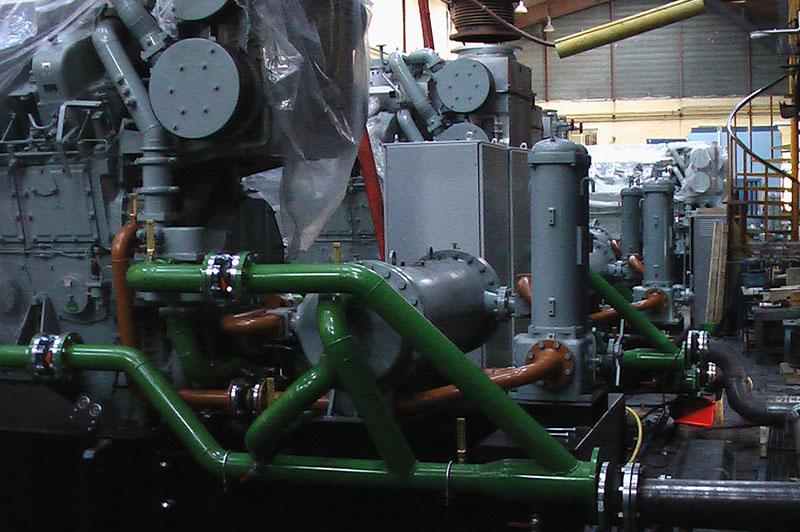

- Fuel circuit: installation of buried or aerial tanks, realization of the connections between the tank and the group, in simple or double envelope piping, steel or polyethylene, installation of the tank equipment (vent, unloading, gauge, filling limiter, suction pipe)

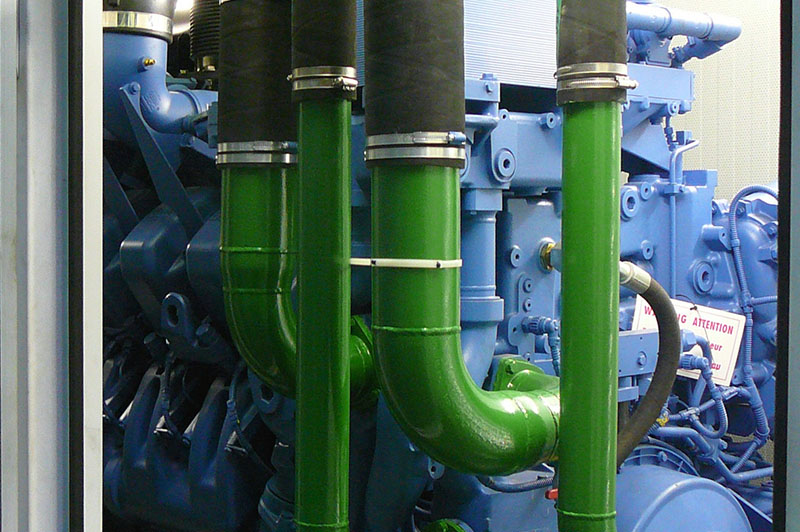

- Cooling circuit: realization of the connections in steel tube between the thermal engine and the coolers, testing of the circuits

- Soundproofing: installation of sound traps in the air ducts, dressing of partitions in absorbent panels

- Ventilation: installation of air grills, room fans, electric shutters

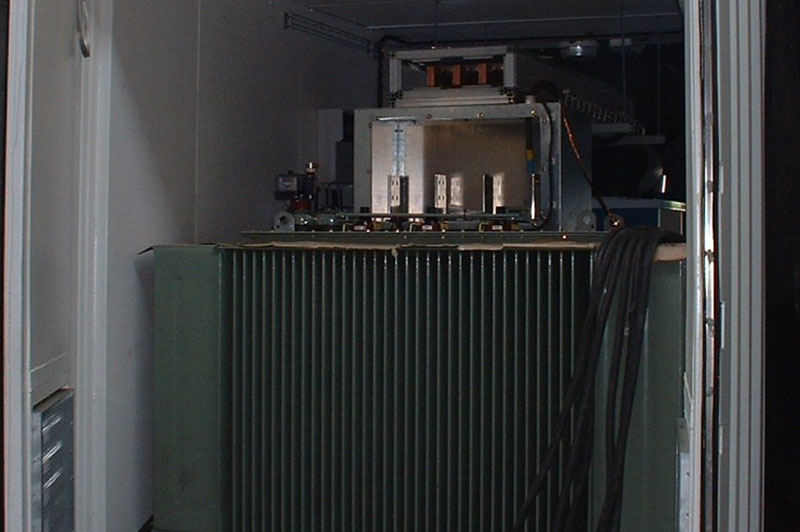

- Electrical installation (high and low voltage): installation of power circuit breakers, cables and cable trays between the alternator, the main circuit breaker and the customer’s main board. Supply and connection of transformers and Low Voltage Boards. Supply and installation of source inverters of all powers. Finished and controlled industrial generator installation.

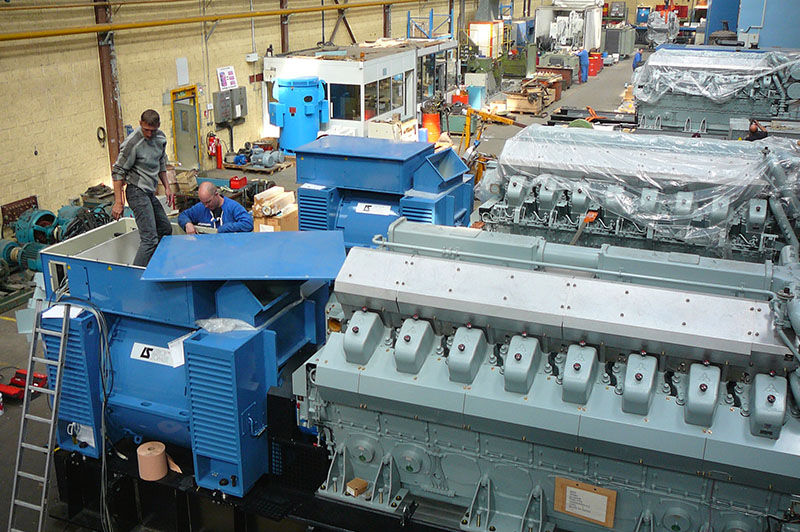

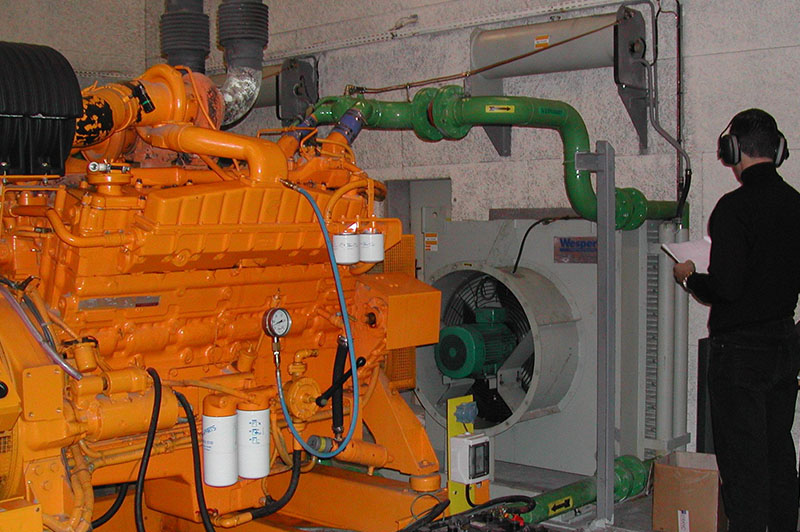

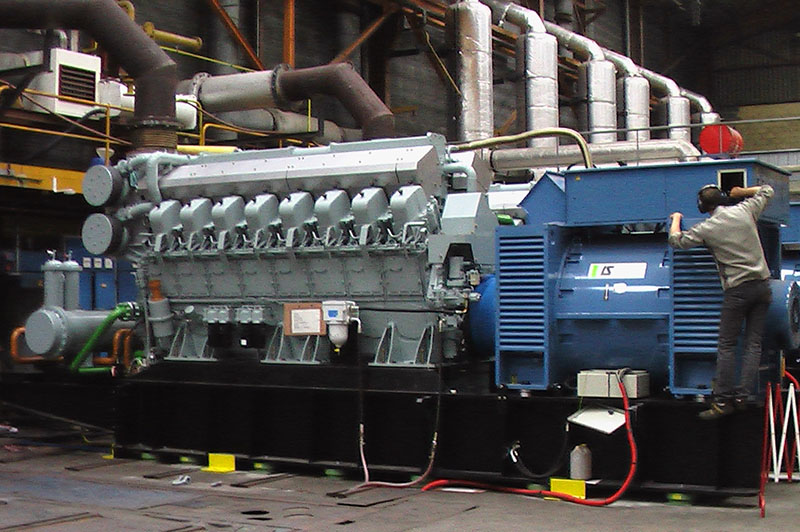

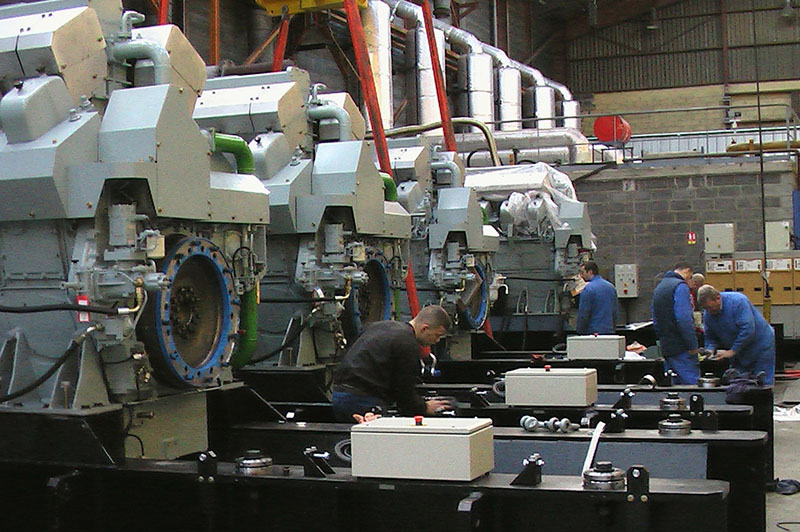

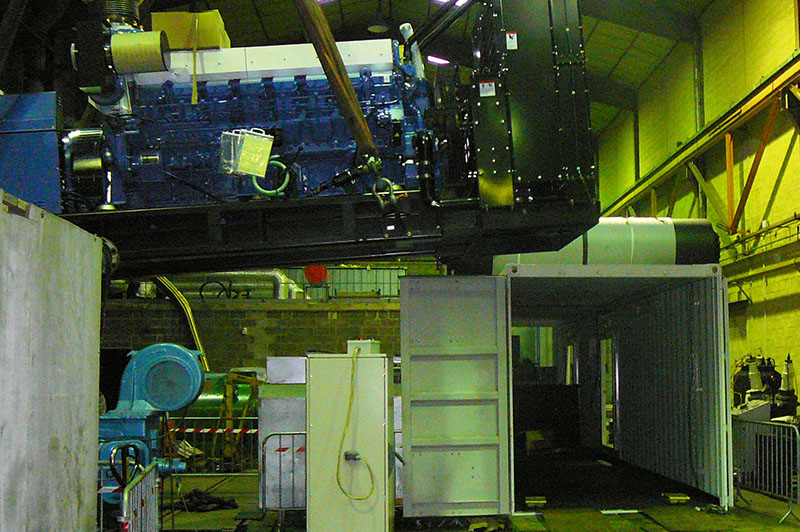

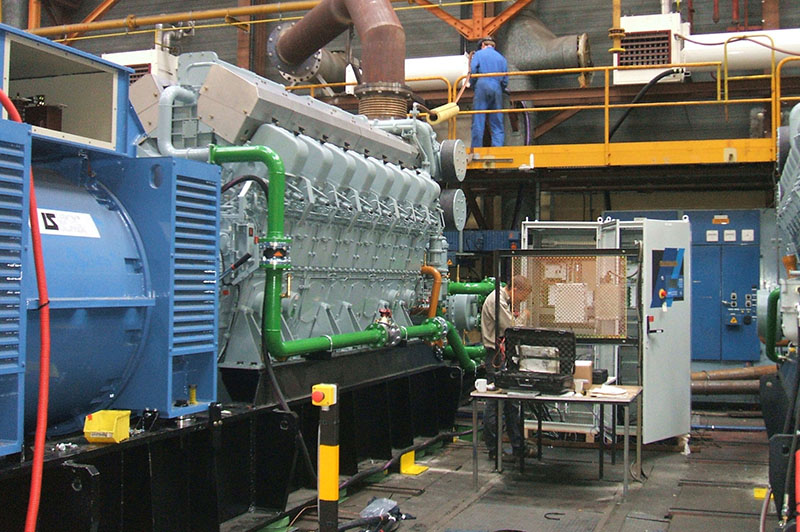

- Possibility of tests and reception platform in our workshops of Seclin:

- For Fuel and Gas units

- Possibility of network simulation for testing coupling sequences

- Possibility of grid coupling tests at 20kV

- Possibility of coupling tests between units

- Load tests on resistive benches

- Possible tests, depending on use, on capacitive or inductive loadbanks

- Training of users’ technical teams in real operating conditions of the equipment

- Endurance tests

- Load impact tests

- Recording of physical and electrical parameters during the test phases

- Tests of the different automation sequences

- Possibility of simulating user departures by PLC and supervision system

- The platform is equipped with :

- Fuel tanks

- A natural gas inlet

- Air coolers for unit testing of generators up to 3550 KVA

- Adapted exhaust outlets and silencers

- Circuit breakers for electrical protection

- Coupling devices between units

- Loadbanks

Commissioning and installation of industrial generators

- Wired controls

- Control of the different circuits (lubrication, cooling, fuel, exhaust),

- Commissioning procedures and checkpoints of engine manufacturers

- Launching of no-load start-up sequences

- Test of the functioning of the safety devices

- Control of the direction of rotation,

- Adjustment of the coupling and load distribution systems.

- Load tests

- Tests on resistive loadbanks

- Tests on capacitive or inductive load banks according to the conditions of use of the power plant

Special solutions

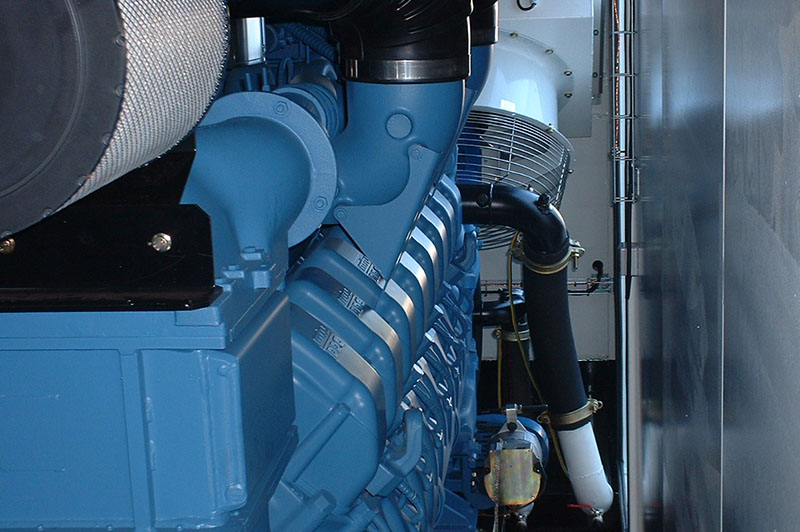

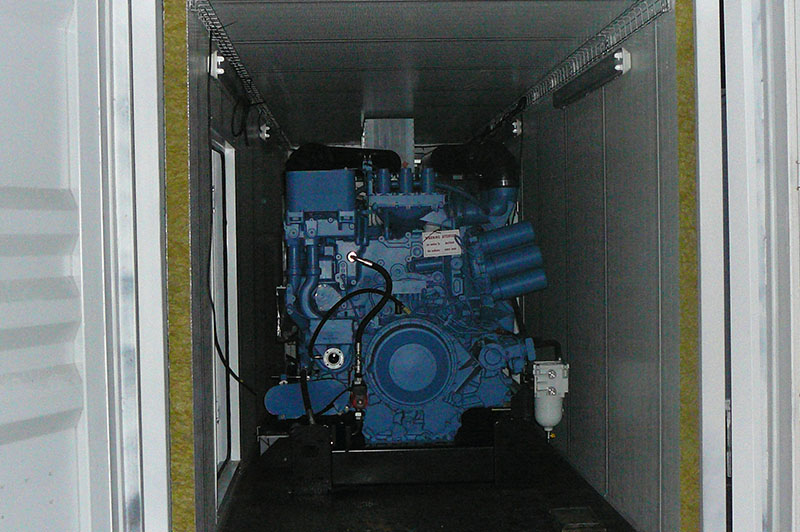

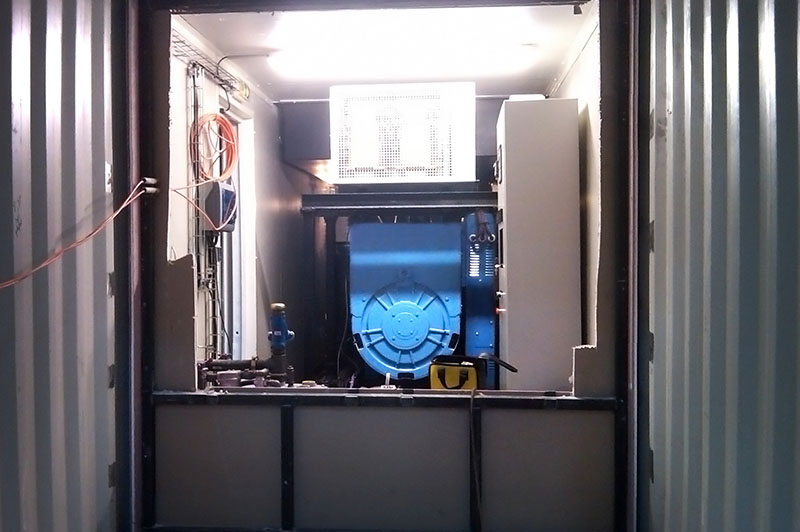

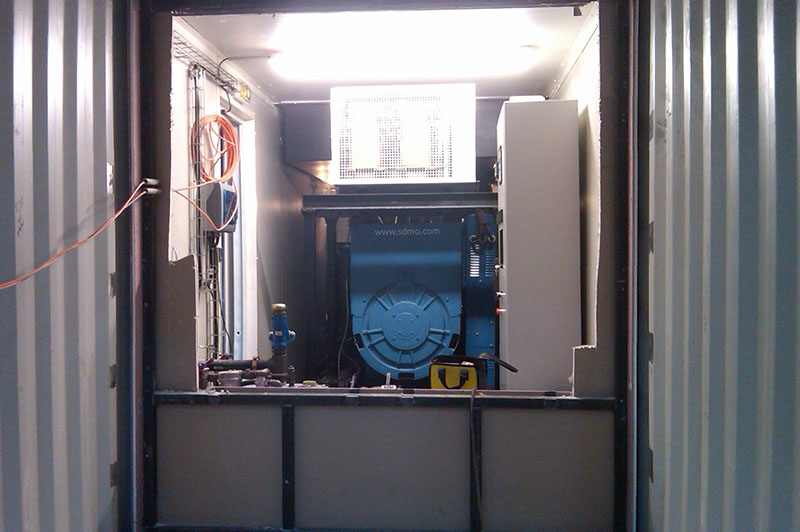

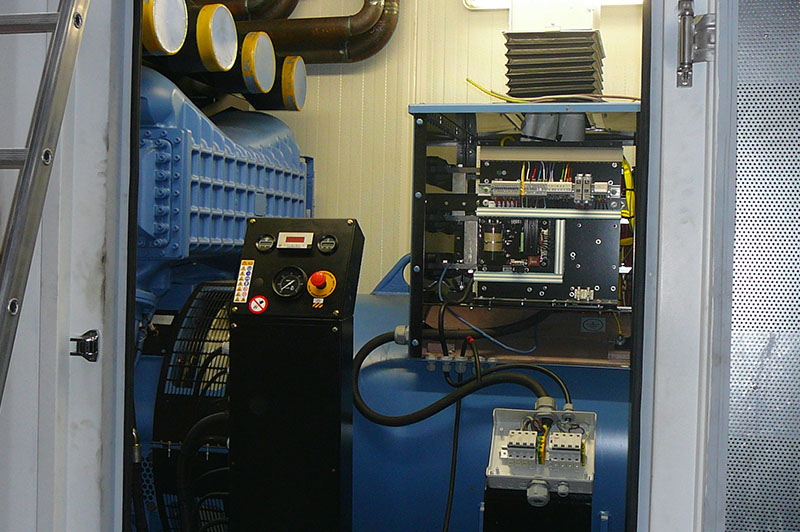

Installation of industrial generator in container according to user’s specifications:

- Study of implementation and constraints (acoustic, firewall, ventilation, environmental, thermal insulation …..)

- Supply of plans in 2D and 3D

- Standard containers (20 feet, 40 feet, high cube)

- Custom made containers (recut sea container, container completely made from ISO corners)

- Containerization of any type of third party equipment (transformers and HV cells, low-voltage switchboards, inverters, dynamic inverters, compressors, special machines)

- Adaptation of the container to the environment of use: tropical countries, very cold containers

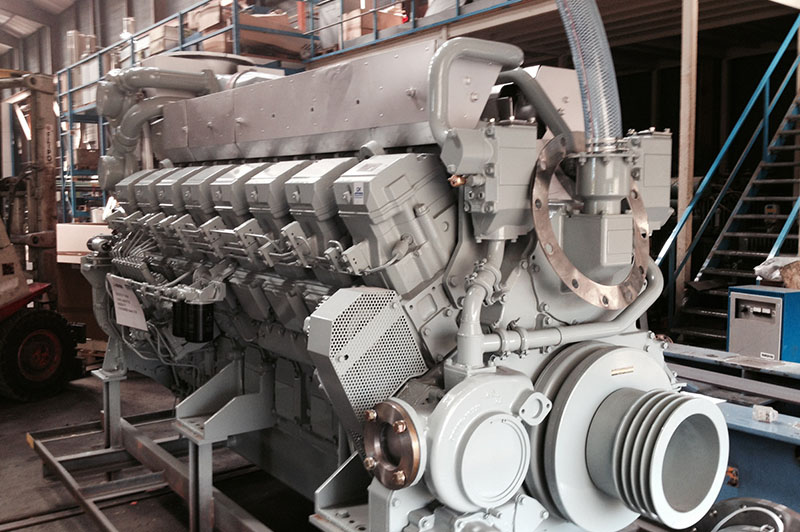

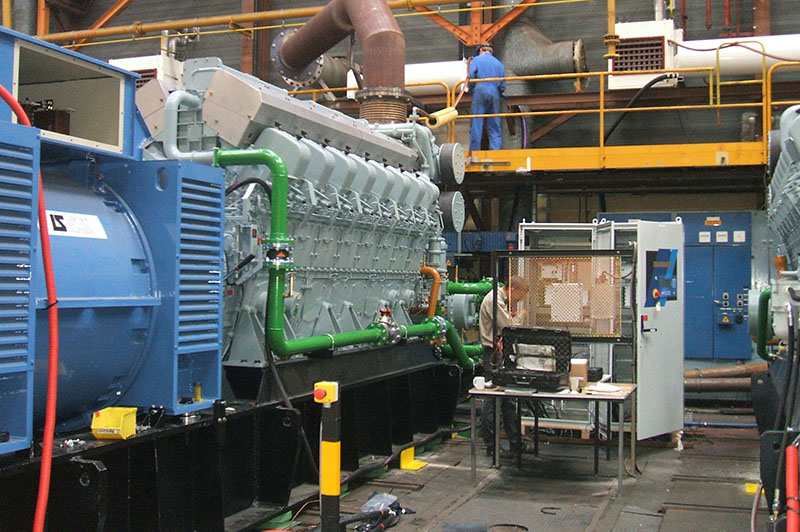

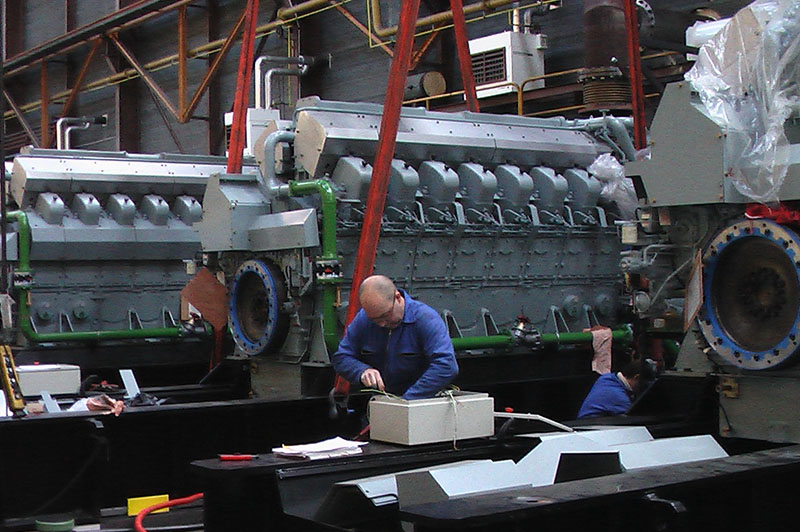

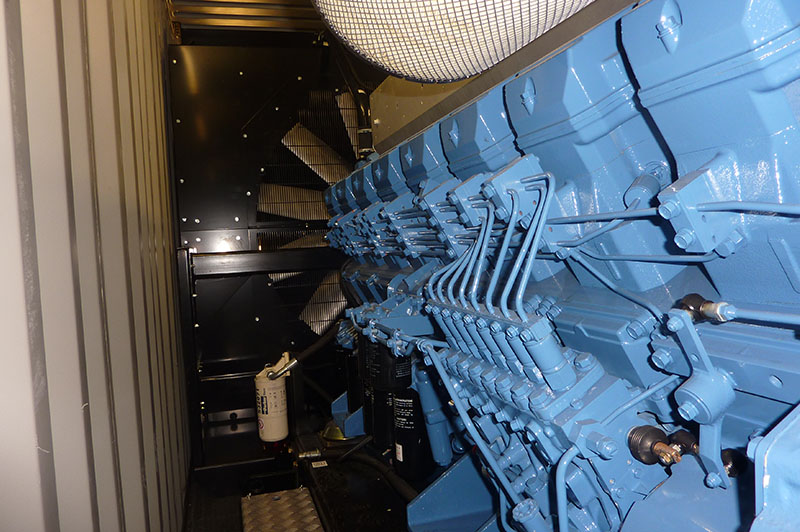

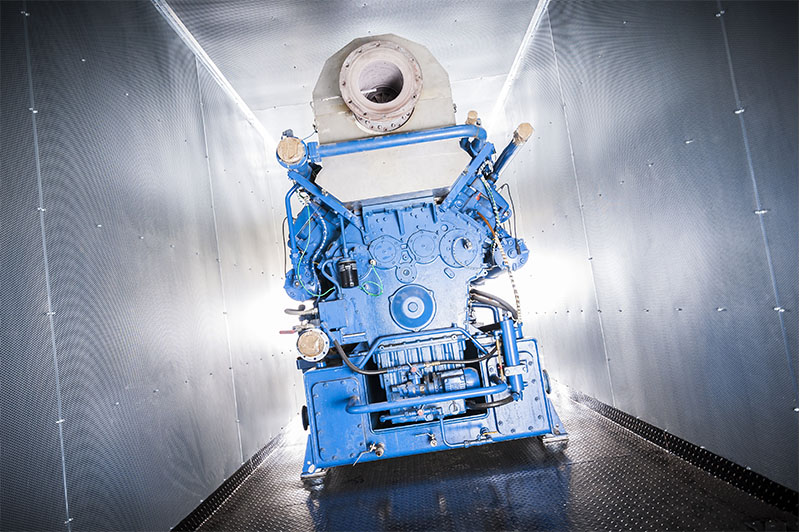

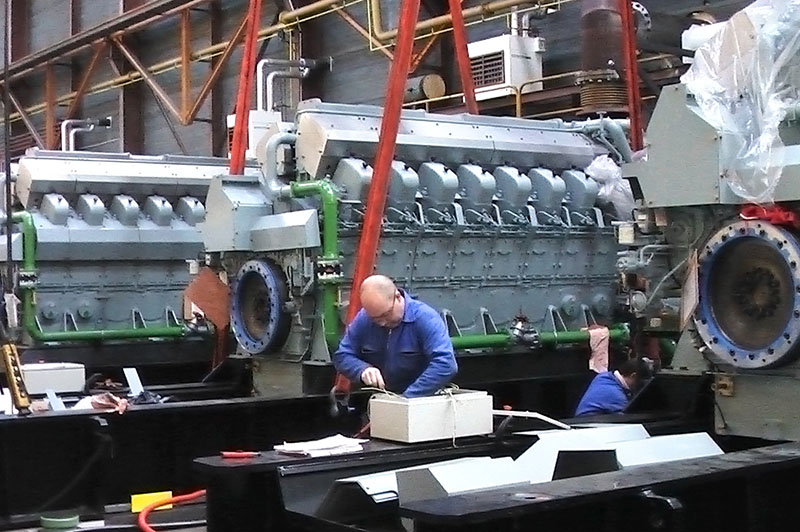

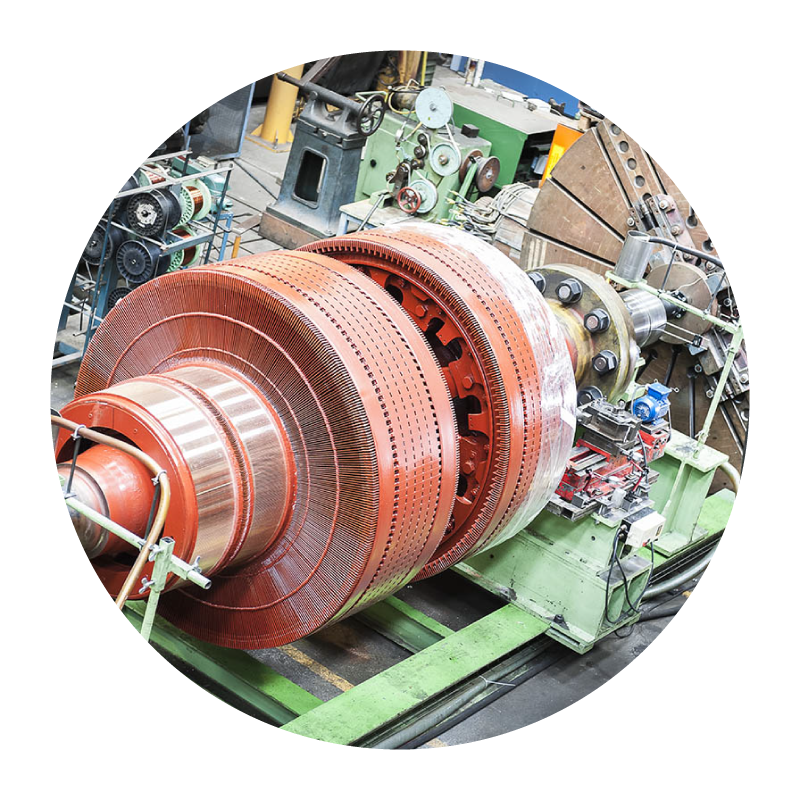

Assembly of special generator units for all types of applications (industry, oil and gas, data centers, tertiary sector, production plants)

- Assembly and installation of industrial generator with remote cooling or heat recovery system

- Assembly and installation of industrial generator units with 2 alternators on the shaft line (lining procedures)

- High power generators with slow motors (750rpm) (laser alignment, stress measurements between crankshaft counterweights)

- Installation of the engine instrumentation

- Platform tests in our premises in Seclin