Maintenance of a synchronous wind turbine generator

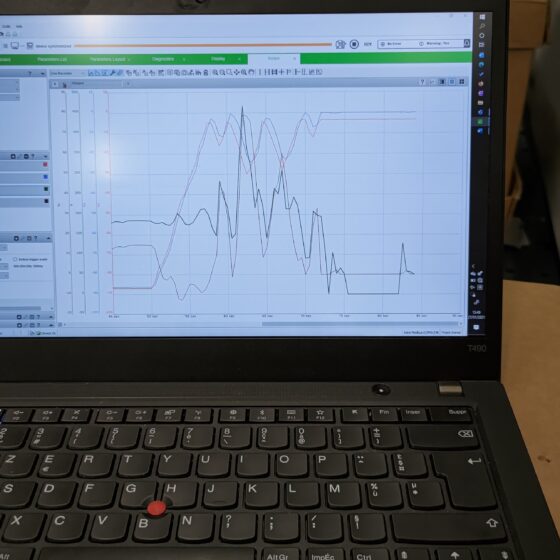

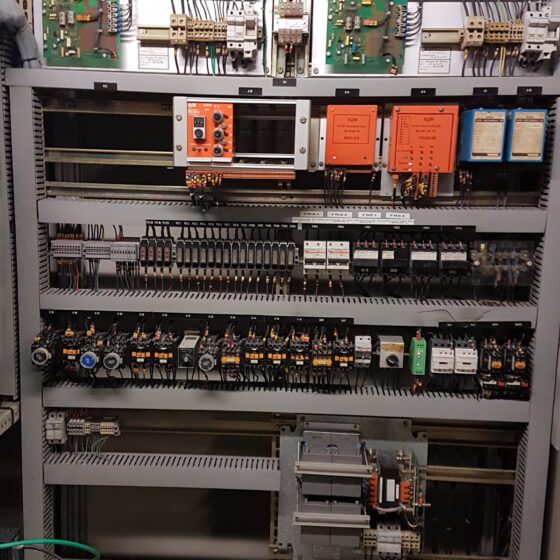

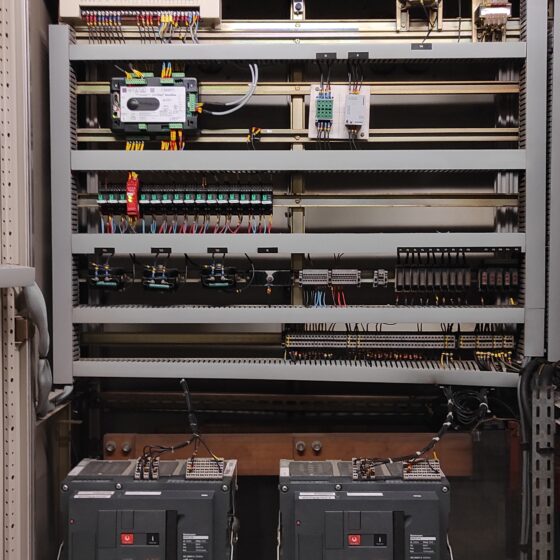

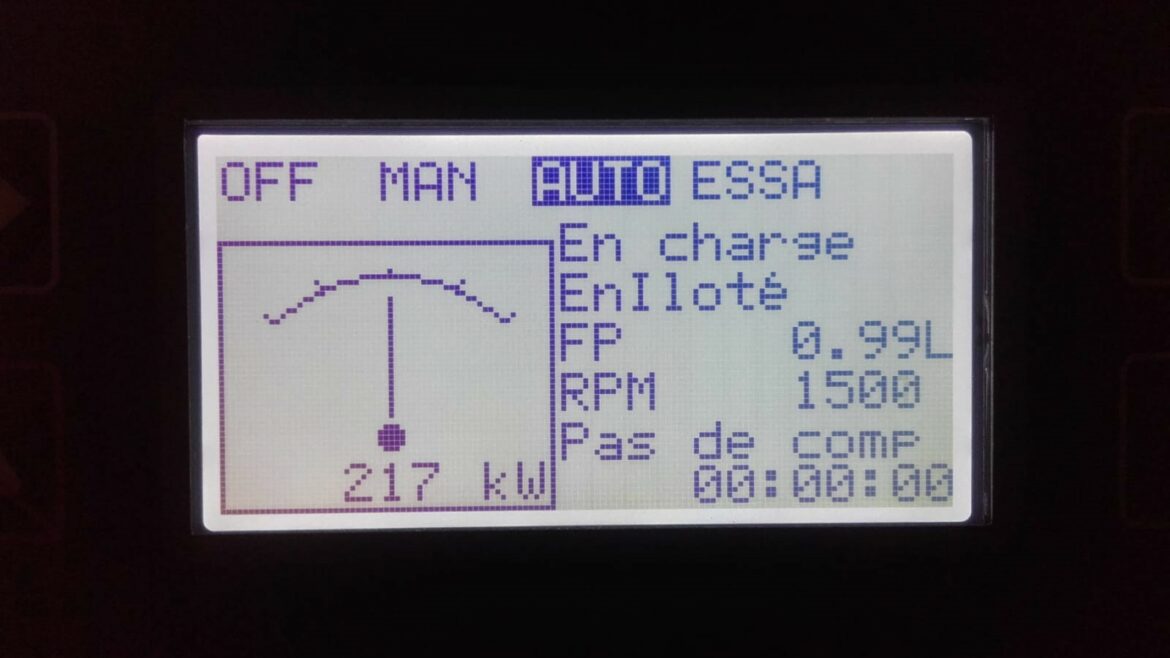

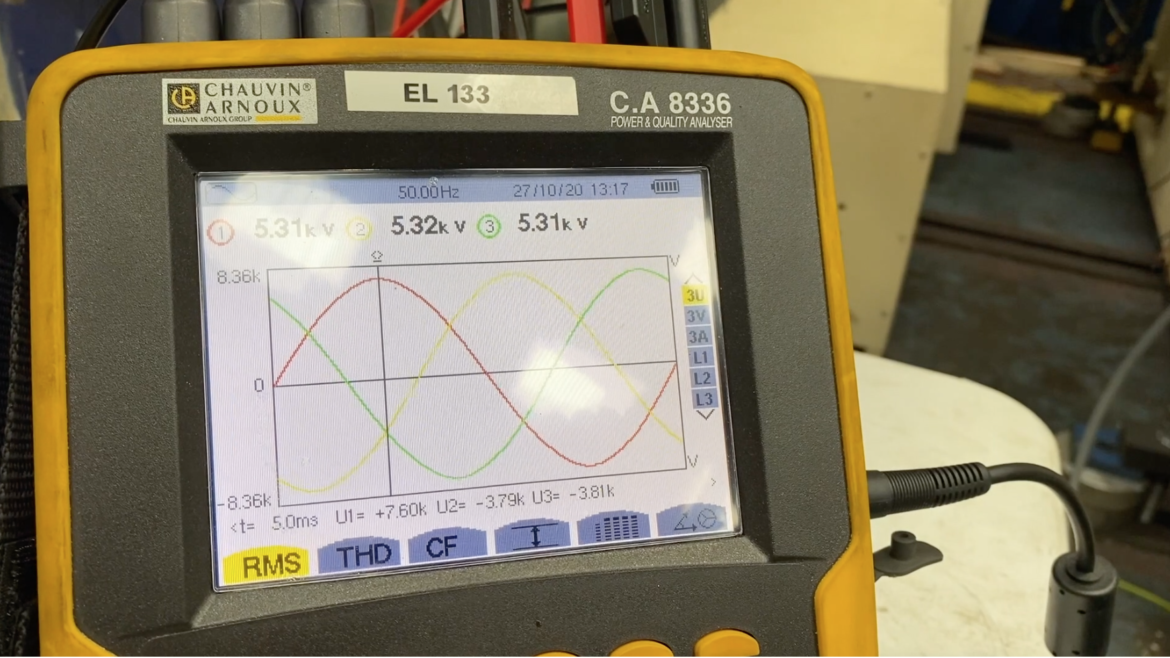

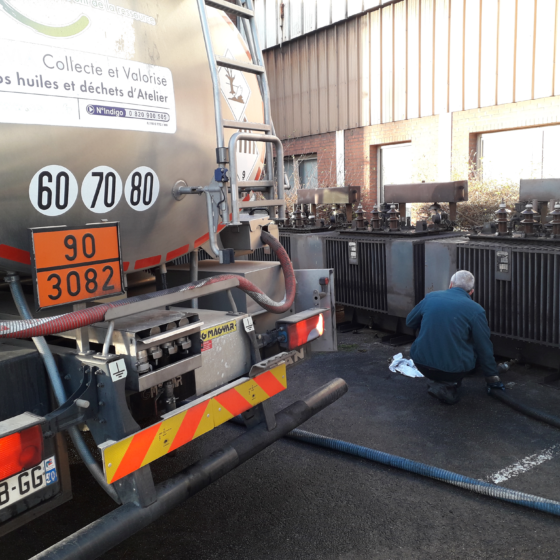

https://www.flipo-richir.eu/wp-content/uploads/entretien-dune-generatrice-deolienne-synchrone-puissance-par-flipo-richir.jpg 458 342 Flipo Richir Flipo Richir https://www.flipo-richir.eu/wp-content/uploads/entretien-dune-generatrice-deolienne-synchrone-puissance-par-flipo-richir.jpgOn behalf of one of our clients in the field of energy production located in the North, we have performed several services. We conducted a maintenance operation of a 600V synchronous wind generator, 3795kVa max, with mechanical and electrical expertise.

We performed preventive maintenance, varnishing and replacement of bearings and seals. This is in view of the rehabilitation of the mechanical subassemblies. Our teams disassembled and reassembled the generator in the workshop in a vertical position thanks to a height under hook of 15 m.